Lithum-ion batteries have transformed electric vehicle technology, providing a sustainable power source that is energy dense, low maintenance and has an extremely long shelf life.

It’s no wonder then that turfcare machinery such as electric utility vehicles, electric scooters and even electric lawnmowers has begun to transition away from diesel and lead acid options in favour of the more eco-friendly lithium-ion. But as demand for electric vehicles and lithium increases, so does the impetus to recycle more of them.

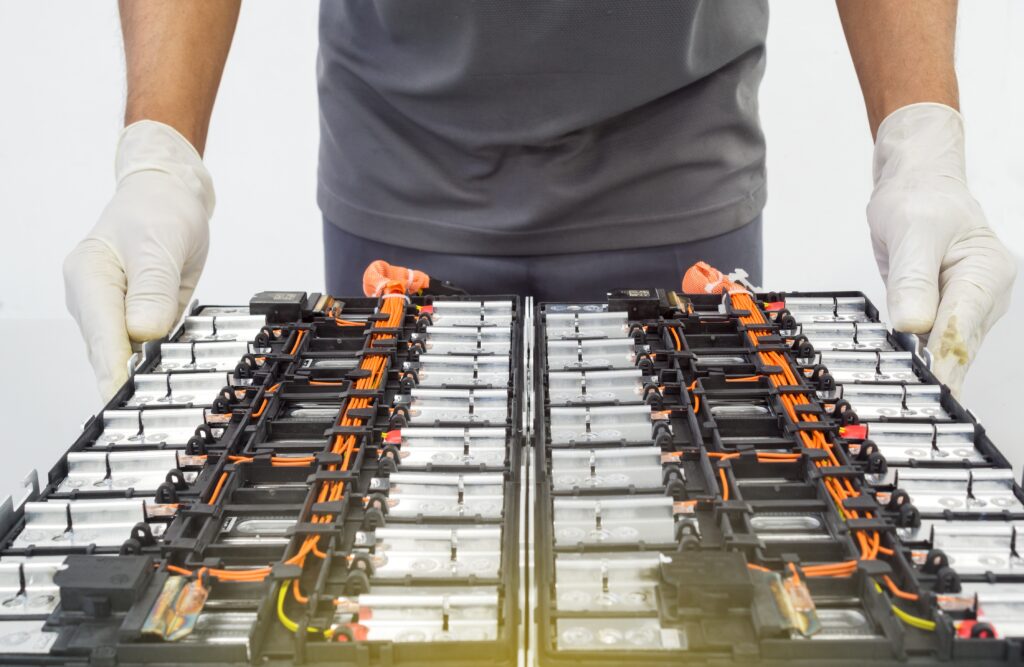

The question is: how do we recycle this new technology once it has fulfilled its job? The most commonly used methods of reusing traditional batteries aren’t suitable for recycling lithium-ion batteries, which are typically more complicated and potentially dangerous when disassembled incorrectly.

Let us explain the process and what to do with your old lithium-ion batteries.

How often do lithium-ion batteries need replacing?

The good news is that lithium-ion batteries can have a long life expectancy if used correctly, so you won’t have to worry about recycling them very often. In general they tend to last two to three times longer than their lead acid counterparts.

When it comes to questioning how long a lithium ion battery lasts, what we’re really talking about is how many charging cycles it has. And this varies from machine to machine, manufacturer to manufacturer, but in proper conditions a lithium-ion battery can last between 2,000 and 5,000 cycles. In comparison a lead-acid battery typically only lasts between 500 to 1,000.

Currently a lithium battery can see up to eight years of use before measures need to be taken to recycle or dispose of the battery.

How it’s done

Used batteries are shredded and their valuable metals, plastics and other materials are filtered based on size and composition.

The lithium as well as other commonly found valuable materials such as cobalt, nickel, and manganese can be extracted and recovered by applying heat in a process called pyrometallurgy. Using this process, up to 95 percent of the key raw materials can be recovered from an electric vehicle battery pack, keeping them out of landfill and general waste.

What’s the science behind recycling lithium-ion batteries?

The raw materials contained within the battery need to be re-used if the electric technology industry wishes to continue developing at the pace it is.

The battery components that make up lithium batteries are more complex than those found in lead acid and therefore the recycling process for used lithium ion batteries is more complex too.

Lithium-ion batteries are among the most advanced forms of commercially available battery technology. Using lithium ions as a main component, which contain a higher number of valence electrons than any other battery type, means these batteries can store more energy for their size.

Like all batteries, a lithium ion battery has an anode, cathode, separator and electrolyte. It’s the battery chemistry between the materials used in the components that make them so unique, with combinations that make these batteries second to none when it comes to energy density and longevity.

Luckily, there are ways to reuse and upcycle lithium batteries for future applications, even if those applications aren’t within another electric vehicle.

As an example, Nissan found that its old lithium batteries were able to retain 60 to 70 percent of their original capacity after the vehicle had been dissembled at the end of its life. That’s not enough to form new batteries or continue to run an electric vehicle, but it makes the battery ideal to be used for less energy intensive uses such as electricity storage at a grid level or in private homes and businesses.

How to extend the lifespan of lithium-ion batteries

Even better than recycling for climate change, is to get the most out of lithium batteries during their lifespan.

To optimise the lifespan of lithium-ion batteries, operators should consider recharging when the battery life gets to 50 percent. Many e-vehicles including the STAR EV range of golf buggies and utility vehicles have intuitive apps that can track the charge of the vehicle so that it can be re-charged at the optimum time.

Doing this doesn’t affect performance. A golf buggy or utility vehicle running on a lithium-ion battery won’t slow down throughout the day, even if they get to a point of depletion.

That being said, avoiding 100 percent depletion can increase the longevity of a battery and its charge capacity in the long-run. STAR EV vehicles come with on-boarding charging so that vehicles can be topped up throughout the day.

What should I do with my battery once it runs out?

Lithium-ion batteries are still in the early stages of their potential and as such business’ recycling processes are something that are under constant development.

It stands to reason that the process will be similar to what many users may have already experienced when recycling lead acid batteries. Companies can use a recycling contractor to take the batteries away to a recycling plant and dismantle them for their precious components to be removed and re-used for new batteries.

To learn more about how your venue could benefit from a STAR EV lithium-ion powered electric fleet, contact Reesink by calling 01480 226800 or visiting or visiting reesinkevehicles.co.uk.